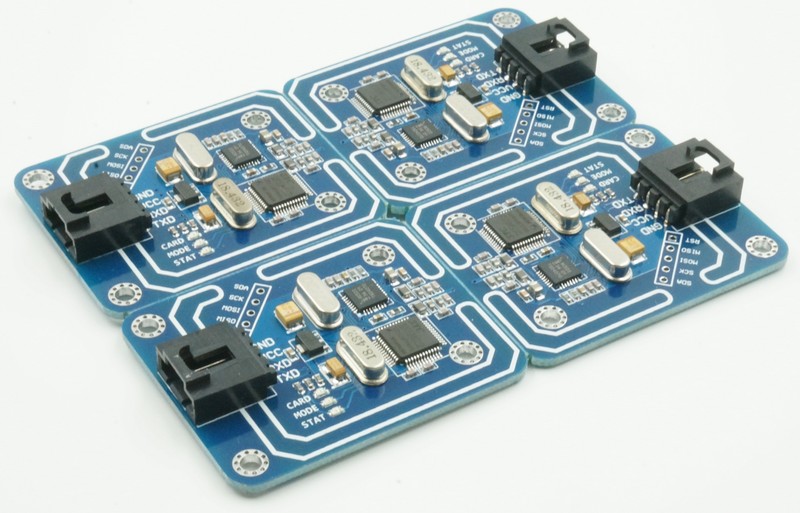

Turnkey PCB Assembly Streamlining Your Electronics Manufacturing from Design to Delivery

Turnkey PCB assembly is a PCB assembly service that integrates design, component procurement, assembly and testing into a unified process. This all-in-one approach not only simplifies project management but also speeds up product delivery cycles. As competition in industries such as automotive, industrial automation and the Internet of Things grows, reliable and integrated PCB solutions are more valuable than ever.

Faster Time-to-Market with Turnkey PCB Assembly and Centralised Production

Time is critical in electronics manufacturing. Delays can result in lost revenue and missed opportunities. Turnkey solutions dramatically reduce development cycles by centralizing all production stages. Manufacturers manage everything under one roof, rather than bouncing between designers, parts suppliers, and assembly lines. This enables quicker transitions between prototyping and mass production.

Additionally, a centralized system ensures that design revisions are implemented more quickly. Engineers and technicians work side by side, allowing for real-time feedback and rapid iteration. This collaborative model eliminates the need for back-and-forth emails and delays caused by misaligned expectations. Businesses benefit from faster launches, better performance alignment, and higher customer satisfaction.

Improved Quality Control and Accountability

One of the major pitfalls in traditional PCB manufacturing is the diffusion of responsibility. When multiple vendors are involved, it’s challenging to pinpoint the origin of an issue. Turnkey PCB Assembly solves this by consolidating accountability. The team that designs your circuit also sources the parts and assembles the board. This cohesion improves both product quality and consistency.

Moreover, a single vendor is vested in delivering high-quality products throughout the process. They are responsible for every stage, from component compatibility to final inspection. This makes it easier to catch and resolve issues early. As a result, product recalls and costly reworks become less frequent. Clients enjoy greater peace of mind and reduced post-launch complications.

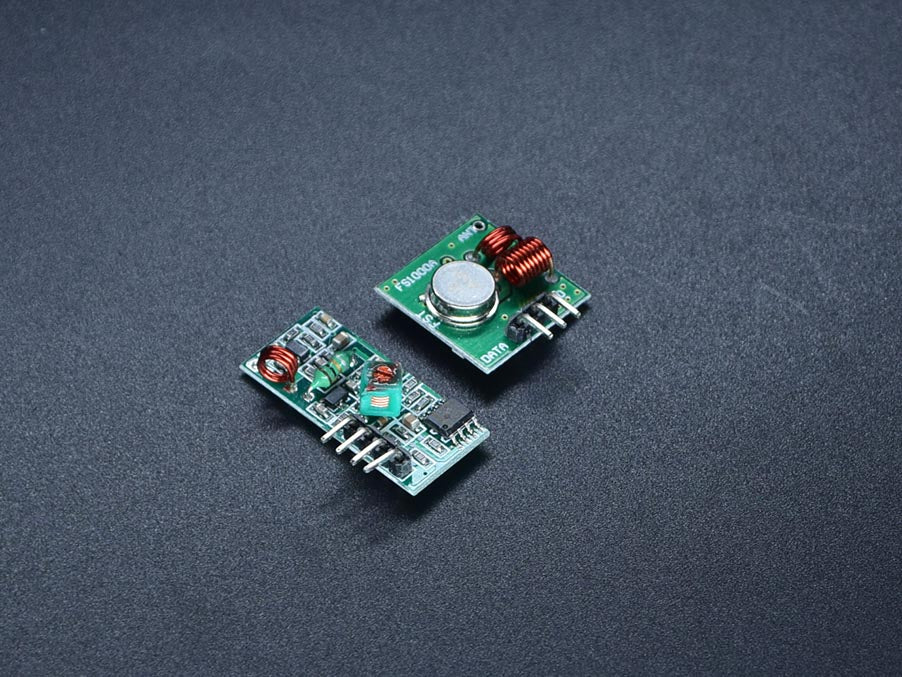

Cost-Efficiency Through Supply Chain Integration

Cost optimisation is a key driver for many businesses turning to turnkey solutions. By consolidating services, companies avoid markups associated with third-party logistics and fragmented production. Suppliers offering Turnkey PCB Assembly often have established relationships with component manufacturers, which means better pricing and availability.

Integrated sourcing also reduces the risk of counterfeit components, which can compromise performance and safety. With all parts vetted and ordered by a single entity, consistency improves. The result is a leaner, more efficient supply chain. Businesses save on materials and benefit from streamlined procurement and logistics, resulting in more predictable budgeting.

Seamless Communication Throughout the Process

Miscommunication can stall projects and derail deadlines. Turnkey PCB Assembly offers streamlined communication by reducing the number of stakeholders involved. Clients communicate with one project manager or engineering team, eliminating the telephone-game effect of dealing with multiple vendors.

This clarity enhances coordination and facilitates quicker problem-solving. Clients receive consistent updates, realistic timelines, and instant answers to technical questions. Additionally, with fewer handoffs, documentation errors and data loss become rare. The streamlined nature of communication helps teams work more cohesively, ensuring that the final product meets all technical and timeline expectations.

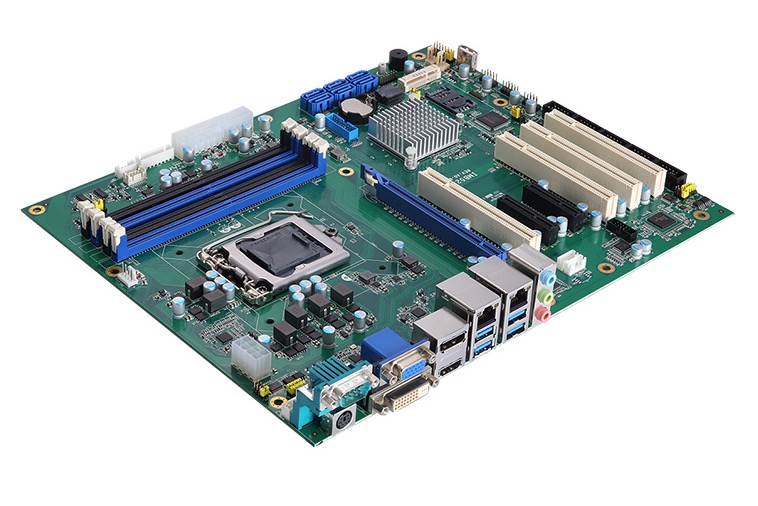

Scalability for Growing Businesses

Startups and SMES often face the challenge of scaling production without overwhelming internal resources. Turnkey PCB assembly provides the infrastructure and expertise needed to grow efficiently. Because the provider manages everything from procurement to testing, smaller companies can scale without significantly increasing overhead.

Moreover, this model is flexible. Whether you’re producing 100 boards or 10,000, turnkey providers adapt quickly. This responsiveness enables businesses to respond to market trends and customer feedback more quickly and effectively. This scalability is crucial for staying competitive in rapidly evolving industries such as wearable technology or smart home devices.

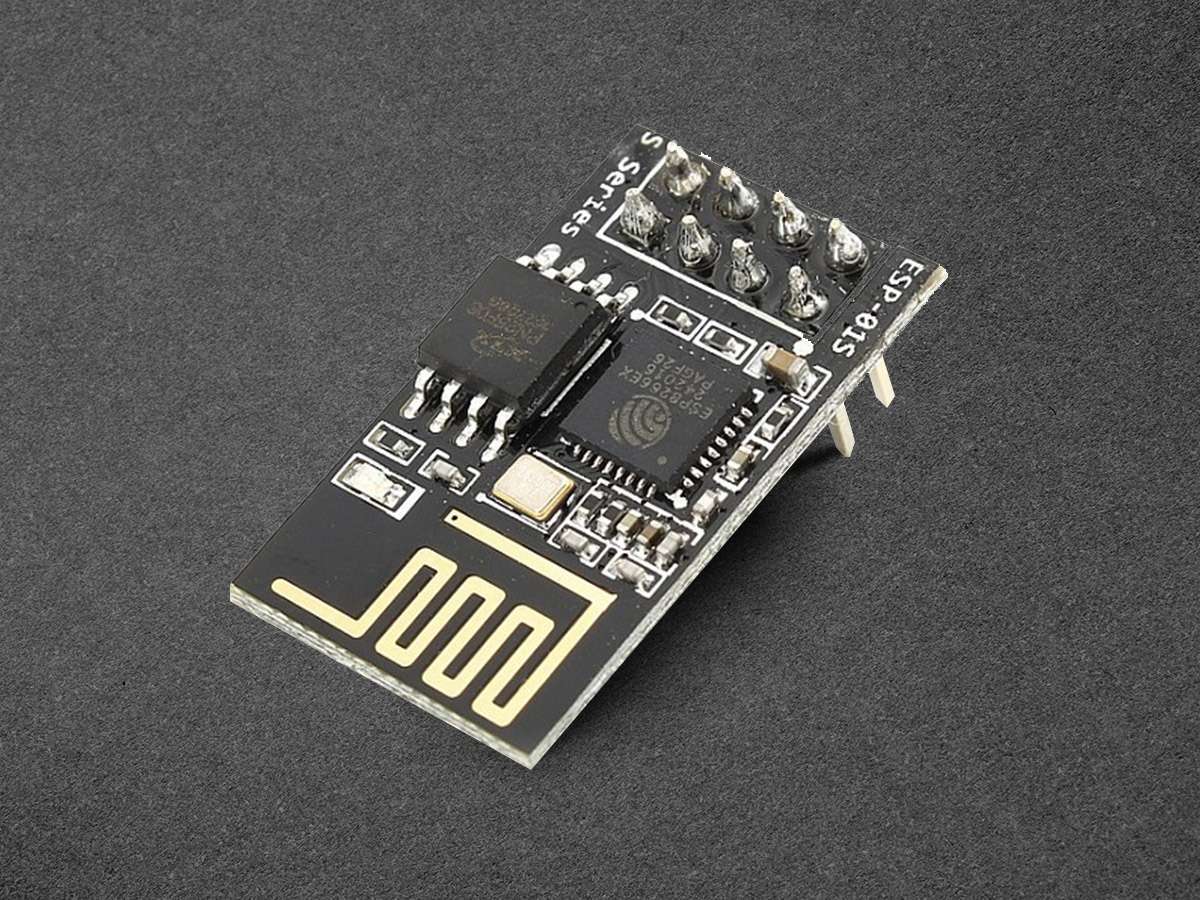

Customised Solutions for Diverse Applications

Every product has unique requirements, and turnkey services are designed to be adaptable to meet these needs. Providers work closely with clients to understand their goals, performance needs, and cost constraints. As a result, they can tailor solutions for various sectors, from medical devices to industrial controls.

Customisation extends beyond design. Turnkey PCB Assembly providers offer testing protocols, packaging options, and compliance certifications tailored to the client’s market. This end-to-end customisation helps companies launch products that meet regulatory standards while standing out in crowded marketplaces.

Turnkey PCB Assembly and the Future of Manufacturing

Turnkey PCB assembly is a vital asset for modern businesses, as it centralizes processes, reduces costs, and enhances product quality. As the demand for faster, more innovative, and more reliable electronic products continues to grow, turnkey solutions will become increasingly valued by businesses.