Smart factories rely on stable and intelligent systems to achieve efficiency. At the centre of these systems is the Industrial Motherboard. It connects equipment, processes data, and ensures operations run without interruption. Unlike consumer-grade hardware, it is engineered for harsh environments and continuous workloads. As industries move toward digital transformation, this technology becomes the backbone of automated manufacturing. Companies that adopt it gain higher reliability, improved scalability, and faster integration with Industry 4.0 platforms.

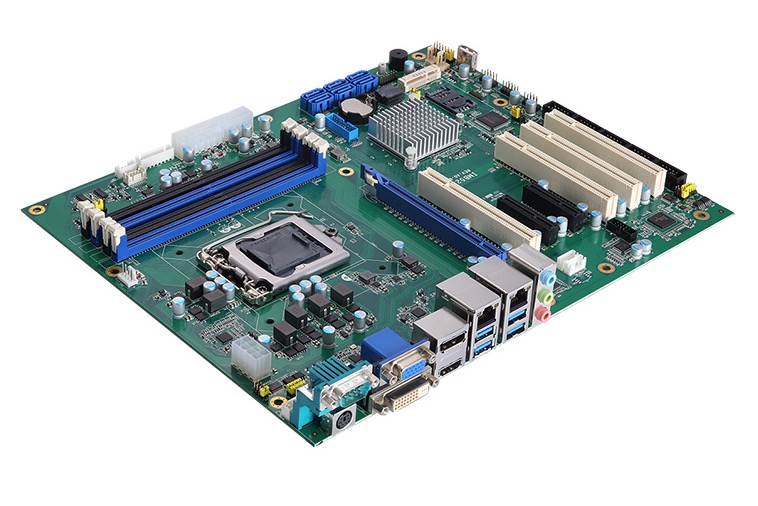

Core Function in Automation

The Industrial Motherboard acts as the command centre for smart factories. It links production lines, robotic systems, and industrial sensors. By processing and distributing real-time data, it synchronises machine movements and workflows. This coordination improves speed and accuracy while minimising human error. For example, automated welding robots rely on quick communication through the motherboard to maintain precision. Without it, smart factories cannot deliver consistent quality. The ability to manage automation efficiently makes it essential in modern production lines where downtime is costly.

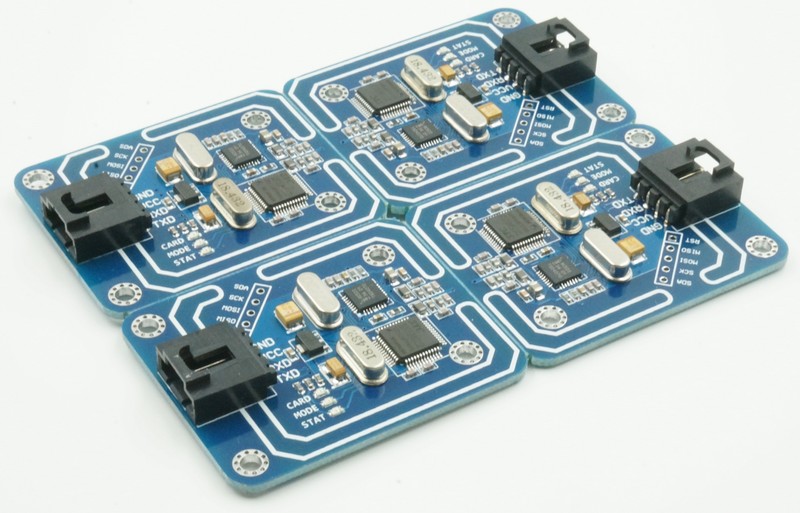

Durability in Harsh Environments

Factories operate under tough conditions that challenge equipment. Heat, vibration, and dust are common in industrial settings. An Industrial PCB is built with rugged materials to withstand these factors. Wide temperature ranges, solid capacitors, and stable power management allow continuous use. This durability extends equipment life and minimises downtime. Unlike standard hardware that may fail quickly, industrial-grade boards offer long-term reliability. Reduced failure rates translate into lower maintenance costs and higher production uptime. Manufacturers value this durability because consistent operation is critical for meeting delivery schedules.

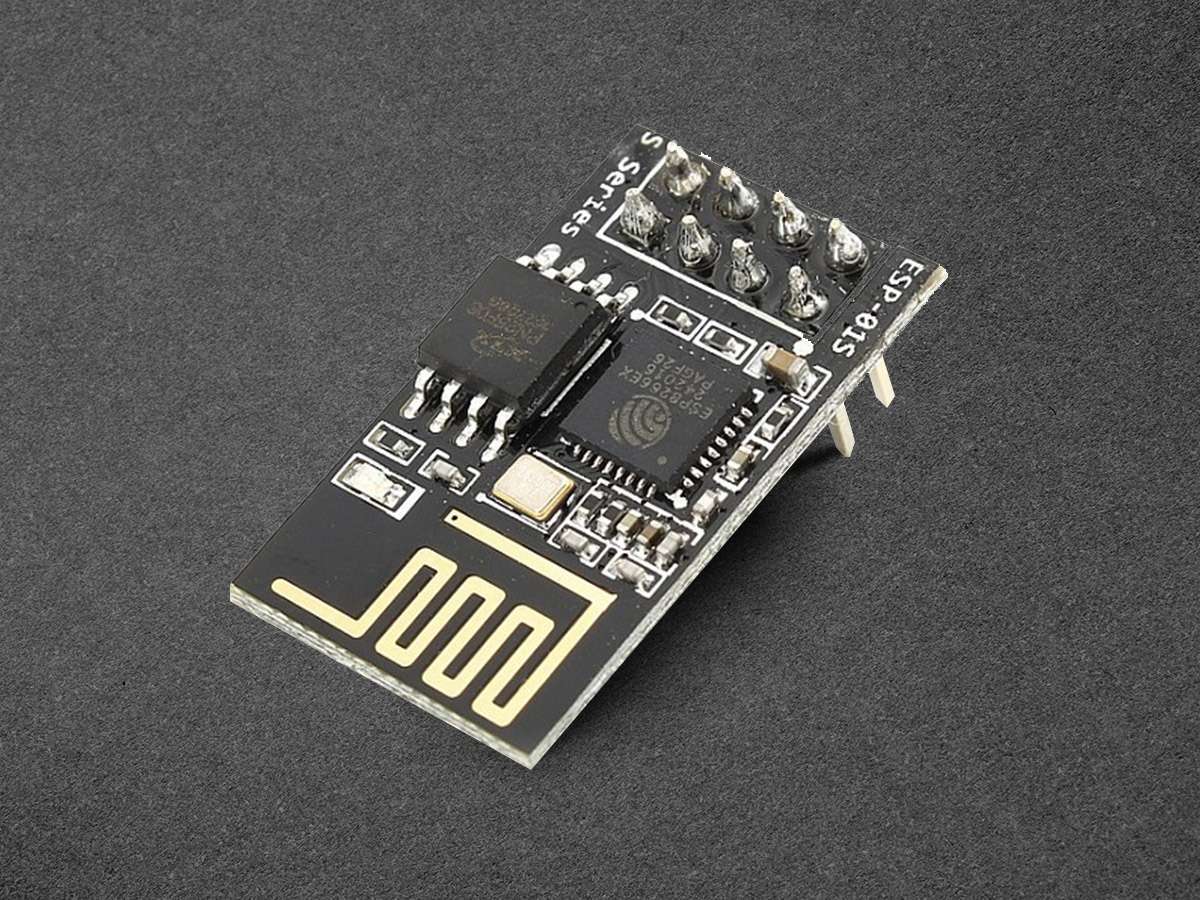

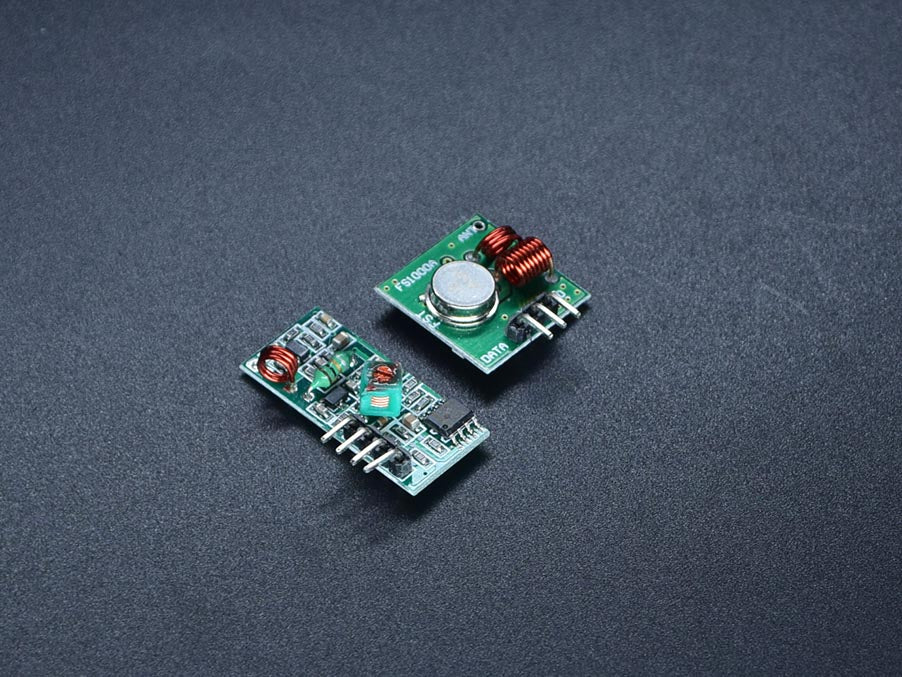

Connectivity for Smart Integration

Integration is vital for any smart factory. Industrial Motherboards provide a wide range of I/O ports, Ethernet interfaces, and wireless modules. These features make it easier to connect PLCs, sensors, robotic arms, and cloud-based platforms. Strong connectivity allows seamless data flow between machines and enterprise systems. For instance, predictive maintenance tools depend on constant data exchange between sensors and central servers. With reliable connectivity, factories avoid bottlenecks and scale faster. As smart factories expand, the ability to integrate both new and legacy systems becomes a key advantage.

Performance for Data Processing

Smart factories generate huge amounts of data every second. An Industrial Motherboard equipped with powerful processors and fast memory handles these workloads efficiently. It supports AI, machine learning, and predictive analytics for real-time decision-making. For example, vision inspection systems use advanced algorithms that require high processing power. By handling data quickly, motherboards help detect defects early, reduce waste, and improve output. High performance ensures machines work at peak efficiency, and production remains stable. In digital manufacturing, speed and precision are non-negotiable, making processing power a core advantage.

Customisation for Specific Applications

Not all factories share the same needs. Industrial Motherboards offer customisation options that adapt to different applications. Expansion slots, GPU support, and legacy ports allow integration with both modern and older machines. This flexibility enables factories to modernise step by step, rather than replacing entire systems. Customisation also supports specialised industries such as medical equipment or aerospace, where unique requirements are common. By tailoring the motherboard, manufacturers reduce costs, improve compatibility, and ensure a smoother upgrade process. A custom-fit solution often determines whether digital transformation succeeds or faces delays.

Security and Reliability in Operation

As factories become more connected, cybersecurity becomes a growing concern. Industrial Motherboards address this with features like TPM modules, secure boot, and watchdog timers. These protections safeguard systems from unauthorised access and unexpected failures. Reliable operation is critical for sectors like automotive and aerospace, where downtime can cause significant financial losses. Enhanced security builds trust in automation and ensures compliance with global standards. Factories can operate confidently, knowing their systems remain stable and protected against threats. Security is no longer optional but a fundamental requirement in smart factory environments.

Final Thoughts on Industrial Motherboard in Smart Factory Development

Industrial Motherboards play a vital role in building and sustaining smart factories. They deliver automation, durability, strong connectivity, and high performance. Their flexibility allows smooth integration across industries, from automotive stamping to aerospace component manufacturing. Security features add another layer of confidence for long-term use. Partnering with an experienced supplier ensures that factories receive tailored solutions and reliable support. By investing in this technology, manufacturers secure efficiency and prepare for future growth. The Industrial Motherboard remains the foundation of smart factory development and digital manufacturing success.